Grimm Knife Company was started by two friends with a love for cooking, the outdoors, and high end cutlery. We pride ourselves on attention to detail, and use the finest steels and most interesting handle material available. Our backgrounds in the New England culinary world gives us a unique insight into knife making, striving to create a balanced blade for the home or professional chef. For more information or to purchase, please contact us.

blades

All Blades are handmade in our workshop in southern Maine. We do not use CNC machines, computers, or robots to make our blades. Our handles are built around the blade for perfect fit and balance. Special attention is given to every blade's geometry with its end use in mind. We strive for a high hardness during the heat treating and tempering process. All high grade Swedish stainless steel (AEB-L) is double tempered as well as cryogenic tempering to further refine the grain of our premium steels for high performance. Want to Check out our blade styles? Click Here.

steel

Nitro V Stainless Steel First released in 2017 this steel was designed and produced in collaboration with Buderus Steel as a version of Uddeholm AEB-L modified with nitrogen and vanadium.

AEB-L Swedish Razor Steel This stainless steel has an incredible combination of durability, edge retention, and ease of sharpening make upkeep on these blade a breeze. An excellent choice for chefs of any skill level.

52100 High Carbon Steel A fantastic reactive steel typically holds an edge longer than most stainless steels. 52100 is able to work longer in between sharpening, however it does requires a little more attention than AEB-L. Recommended for more experienced users.

High Carbon Damascus A reactive steel comprised of 5160, 15N20, and Ni200. 400-500 layers depending on the pattern, ask about our current stock. Extremly sharp with great edge retention.

Still not sure which steel is right for you? Please feel free to contact us, we’d be happy to assist you with any questions.

Looking for more detailed information on AEB-L Swedish Razor Steel and/or 52100 High Carbon Steel? Check out Knife Steel Nerds by Larrin Thomas. His website is full of comprehensive information regarding steel used in knife making, an amazing resource to be sure.

Handles

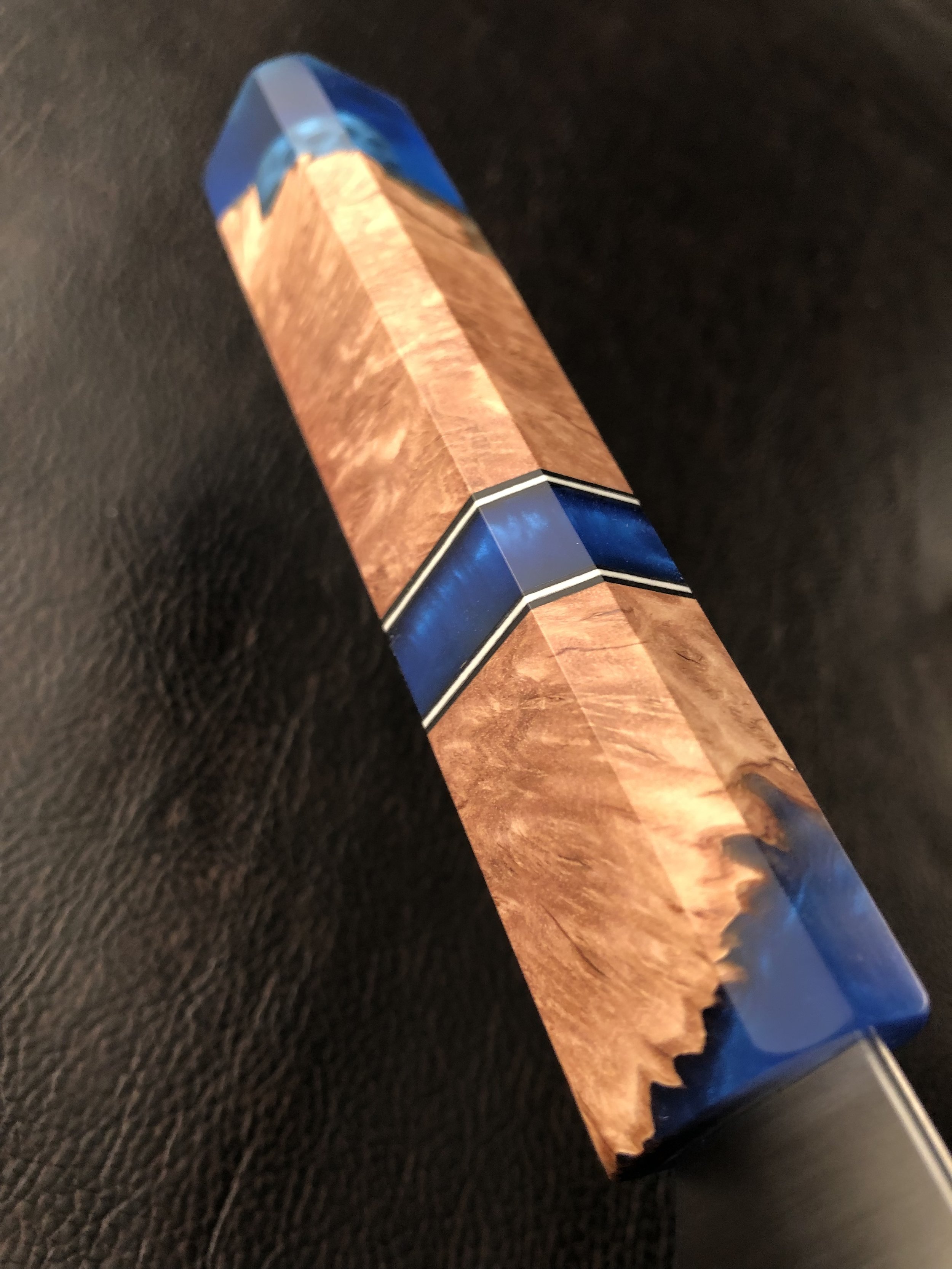

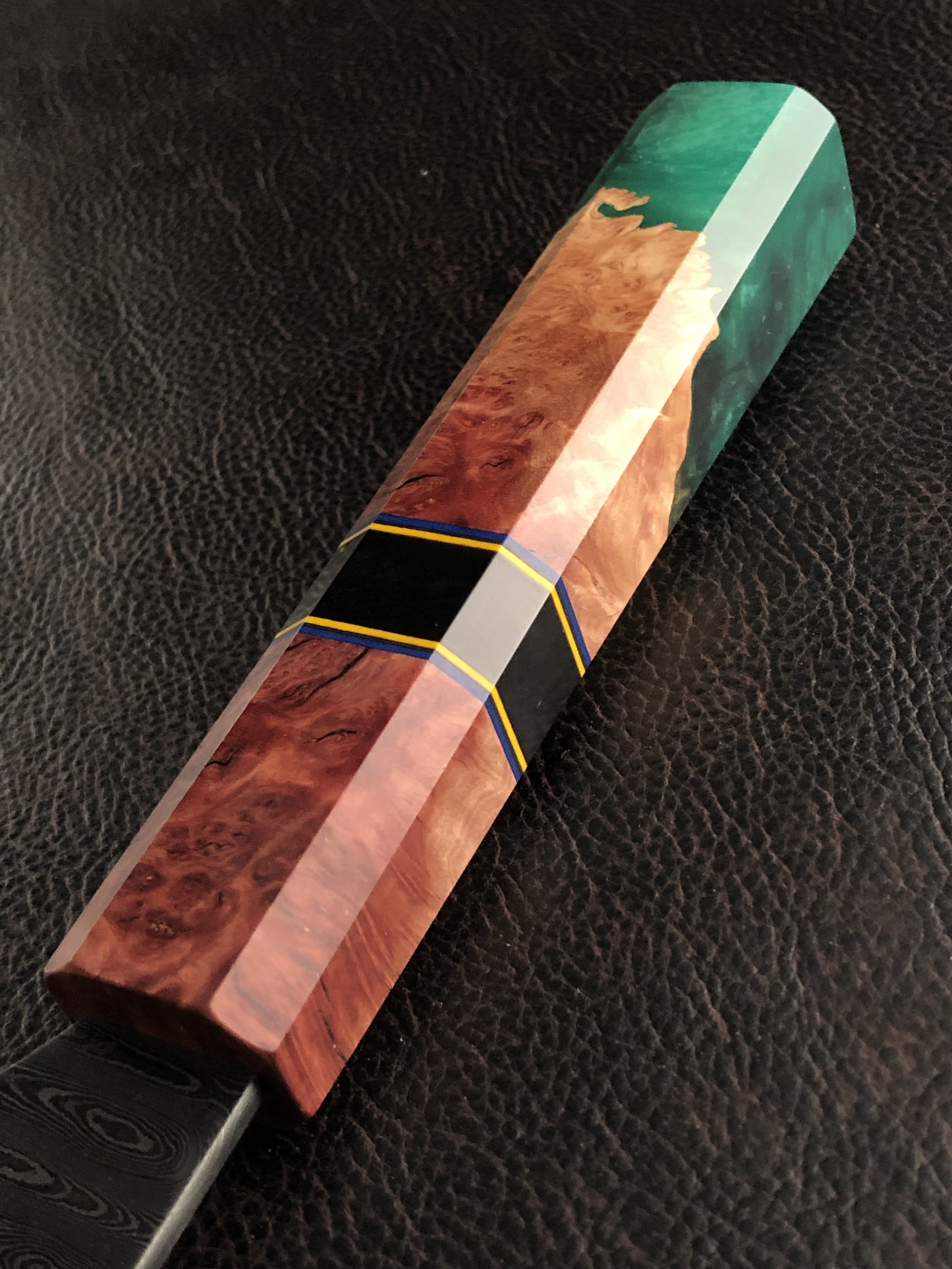

Every handle is a one of a kind work of art. Patterns and color combinations are never completely reproduced. When you own a Grimm Knife Co. handle you can be sure it is as unique and different as you are.

We strive to use the most interesting materials available, from exotic wood burls and tropical hardwoods to high end man made composites and everything in between, we are constantly searching out new and different materials to use for our handles.

Each handle has a surprisingly comfortable hexagonal shape which is ergonomically designed to avoid “hot spots” and fatigue.

Whether you are looking to start a custom knife build from the ground up or want to purchase a prebuilt knife from our Shop or one of our Retailers, we’ve got you covered.

Do you have an idea for a handle? We are always taking on custom projects and love a challenge. Contact Us with you idea today. Let’s make it happen!

Saya

Saya (鞘) is the Japanese term for a scabbard, and specifically refers to the scabbard for a sword or knife. The saya of a koshirae are normally manufactured from very lightweight wood, with a coat of lacquer on the exterior.

Our standard saya is made from walnut and poplar. These are the perfect add-on to any Grimm Knife Co. pruchase. Sayas are great for keeping your blade (and your fingers!) safe when you are not using you knife.

Looking for something other than walnut and poplar? We offer sayas made from highly figured woods. Our stock is constantly changing, so be sure to ask for our current stable of select woods.

©2019.Allan Dines